This UV curing system facilitates the peeling of UV tape after UV exposure. The tape is UV tape for surface protection during back grinding and the dicing of tape in the wafer processing process.

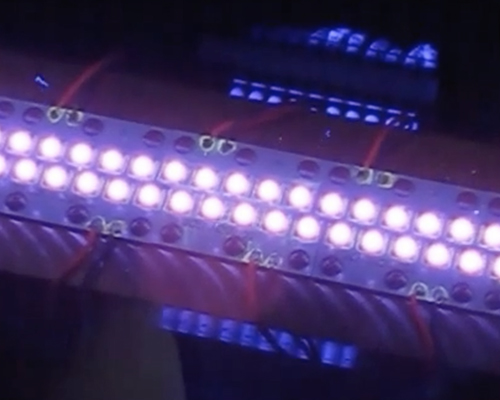

UV-LED curing systems use 365 nm wavelength LED (light emitting diode) light sources for UV exposure. LEDs provide numerous performance benefits.

Thanks to the high-output LED drivers and water cooling systems developed by Technovision, we can provide reliable exposure outputs of 250 mW/cm2 (at a 10 mm working distance).

| Model | Wafer/Frame size | Dimensions |

|---|---|---|

| UVC-200 | 200mm | 750mm(W) × 640mm(D) × 575mm(H) |

| UVC-300 | 300mm | 750mm(W) × 640mm(D) × 575mm(H) |

| 1 | Room temperature exposure. |

| 2 | Low operating costs. |

| 3 | Long life. |

| 4 | Low power consumption. |

| 5 | Safety when replacing light sources. |

| 6 | N2 purge function. |

| 7 | Tabletop design. |