– Domestic sales only –

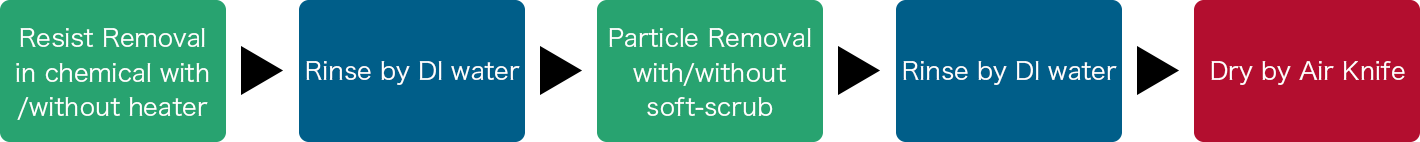

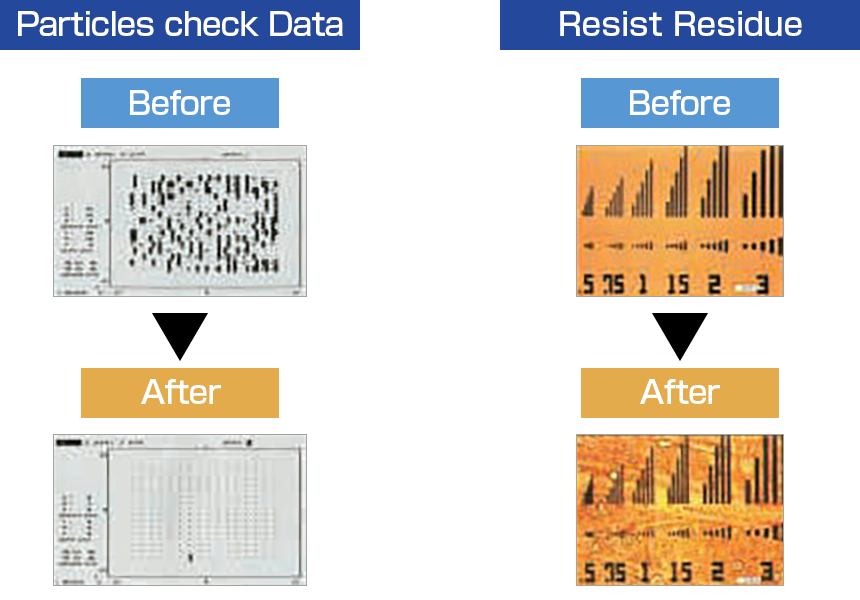

The fully automatic TWC-304A mask cleaning system automatically removes resist residue and particles larger than 1 μm that adhere to the mask.

The fully automatic TWC-304A Cassette to Cassette mask cleaning system can be used with the specified chemicals to achieve greater productivity.

The drying process is based on heated deionized water drying, instead of conventional air knife drying. The design does not require adjustments for water splashes. Hot-DI Water dry

Supports mask sizes up to 14 inches. Simply press the Start button after inserting a cassette onto the machine (Loadable 2 mask cassettes and maximum cassette capacity: 5 pieces).

| Power | 200VAC 3Phase |

|---|---|

| Size | 1,800mm(W) × 1,370mm(D) × 2,150mm(H) |

| Weight | 約650Kg Approx. 980kg |

・Ensures complete removal of resist and resist residue.

・Ensures complete removal of particles exceeding 2 μm.

・The mask is permanent.

・The latest dedicated chemicals are mild and eco-friendly.

・Eliminates the hazards associated with handling hot sulfuric acid and sulfuric acid-hydrogen peroxide (Piranha clean).

・Scrub washing does not scratch mask surfaces.

・Standalone system accommodates double-sided mask cleaning.

・Compact dimensions save space.

*The masks assume change when xpose 100 times a day and 5 or 6 kinds of masks are used for the one product.It calculated for 50,000 to 80,000 yen a mask.

■Best suited for cleaning of photomask larger than 2μm design rule L / S(Line and space)

such as FPD (flat panel display), MEMS devices, fine patterns PCB / FPC / TAB, compound semiconductor, electronic components and thin film.